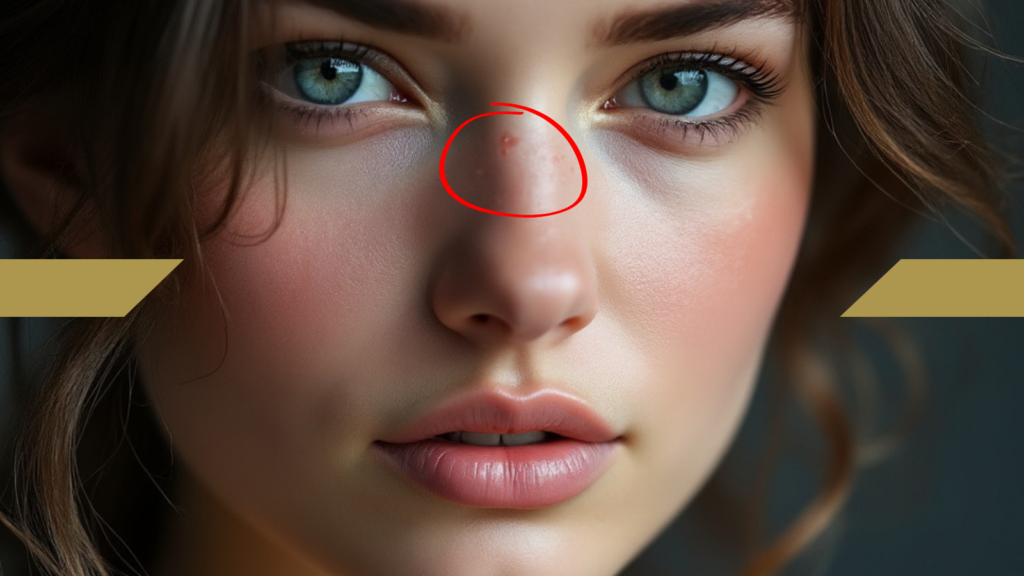

Yes, marks and blemishes on new silicone or TPE (thermoplastic elastomer) dolls are common, and they often stem from the unique properties and manufacturing processes of these materials. Here’s why they can appear even on brand-new dolls:

1. Manufacturing Process

Molding: Both silicone and TPE are cast into molds during manufacturing. Tiny imperfections in the mold or residue from previous production can sometimes leave minor marks or blemishes on the doll’s surface.

Demolding and Cooling: Removing a doll from a mold can cause slight indentations or marks. While manufacturers try to minimize this, some imperfections can still occur.

Cooling Process: After molding, the cooling process can sometimes lead to subtle shrinkage or texture variations in TPE and silicone, creating minor visual inconsistencies.

2. Material Sensitivity

Softness of TPE and Silicone: These materials are designed to be soft and realistic, which also makes them prone to slight indentation and pressure marks. Just lying on a surface during storage or transit can cause faint impressions.

Color Sensitivity: Silicone and TPE are often dyed to achieve lifelike skin tones, and the dye may settle unevenly, especially around joints or edges, which can create faint color blemishes or inconsistencies.

3. Handling and Transportation

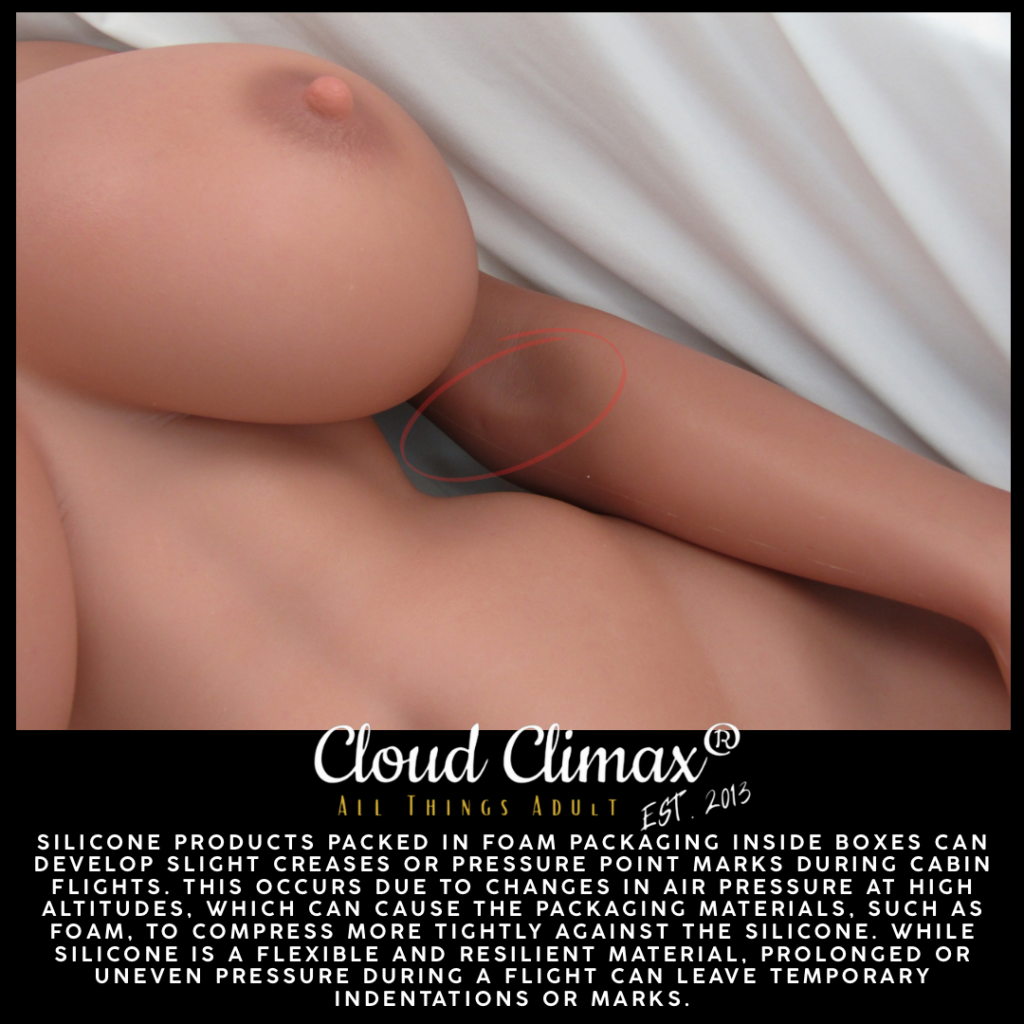

Pressure Marks: Silicone and TPE are sensitive to pressure. If the doll is packed tightly or compressed during shipping, this can leave marks or indentations on the material.

Vulnerable to Dust and Oil: These materials are slightly tacky, so they can attract dust, lint, or oil residues from handling. These can create minor blemishes that may not be removable without thorough cleaning.

4. Long-Term Storage and Exposure

UV Light and Heat Sensitivity: Both TPE and silicone are sensitive to UV light and heat, which can sometimes create very faint discoloration or spots if the material is exposed for too long, even briefly in storage or shipping.

Micro-Tears or Scratches: Due to their soft texture, these materials can also sustain micro-tears or scratches more easily than harder materials, especially during handling.

Minimizing and Managing Marks

While some marks are unavoidable, gentle cleaning, powdering, and proper storage can minimize their visibility and prevent new ones from forming. For example, baby powder or cornstarch can be used on TPE to reduce tackiness, and UV-protective storage can reduce discoloration. Additionally, mild heat application (like a hairdryer at low temperature) can sometimes restore TPE marks by reshaping slight dents.

In general, these minor imperfections are a trade-off for the soft, realistic texture that TPE and silicone materials offer, and manufacturers typically accept a certain level of blemishing as a standard within quality control limits.